About

Completed

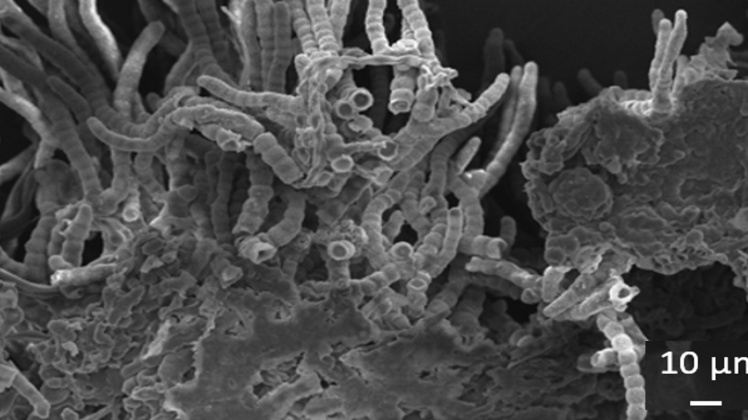

| Project POLYCER: Exopolysaccharide application on industrial ceramic powders used in unidirectional dry pressing process for performance optimization This research is a consequence of the European and international growing interest towards the importance of biogeochemical processes in different technological and commercial areas, such as the case of ceramic industry. Nowadays several organic additives (deflocculants, biocides, antifoams, binders, lubrificants, plasticizers) are added into ceramic slips, to achieve uniform and homogeneous suspensions, conditioning the performance of spray-dried ceramic powers. Nevertheless and in spite of the while range of synthetic additives that are introduced in the splits following the pre-established formulations, an important variability associated with the performance of the conformed products is also reported. In addition, some commonly used additives are toxic for human health and are in general expensive, increasing the final unit cost of the ceramic materials. Several bacterial and fungal species naturally occurring in ceramic raw materials, such as Aspergillus, Penicillium and Aureobasidium, are know to produce exopolysaccharides (EPS).These polymers excreted by the cells are of widespread occurrence and may confer unique and potentially interesting properties with potential industrial uses, such as viscosity control, gelation and flocculation. The aim of the project is to evaluate if EPS produced by the microorganisms natural occurring in the ceramic raw materials and by the fungus Aureobasidium pullulans, contribute to enhance the performance of spray-dried powers when subjected to unidirectional dry pressing (conformation). The project appears as a contribution for sustainable development of ceramic industry, namely through the improvement of the performance of the spray-dried powders during the unidirectional dry pressing process, through the use of EPS. Some positive aspects related to the use of EPS must be mentioned: reduction of the environmental impact caused by synthetic organic additives, reduction the production costs, as well as the costs related with the operator protection systems, gaseous effluent treatment, among others. This aim will be achieved through an intensive research programe, which take advantage of the complementary competences of the partners involved (academic and industry)and mainly incorporate laboratory-based experimental studies, isolation and identification of microbial communities developing in the ceramic slips, EPS production and introduction into ceramic aqueous suspensions and into spray-dried ceramic powers. Finally the evaluation of the effects of EPS in the performance of different produced ceramic bodies (slips and spray-dried powers) will be evaluated. |

Keywords

Eco-innovative materials

Engineering

Environment

Start Date

CERENA Role

Coordinator

Coordinator/Local PI

Integrated Member

Assistant Professor

CERENA Team

Proponent Institution

CERENA / IST-ID, Portugal

Partners

Rauschert Portuguesa, SA

Funding Programme

FCT Grant number 126712

Total Funding

49 687,00 €

CERENA Funding

49 687,00 €