This project has a relevant contribution to the following CERENA strategic areas:

- Physical, Chemical and Biological Processes

Supervisor: Francisco Lemos

Co-Supervisor: Ana Marques

The development of customized microcapsules enables a series of eco-innovative and sustainable materials, such as

a) self-healing materials and coatings;

b) one-component glues;

c) on-demand degradable resins and de-bondable adhesives to target the urgent need for recyclable materials and composite structures.

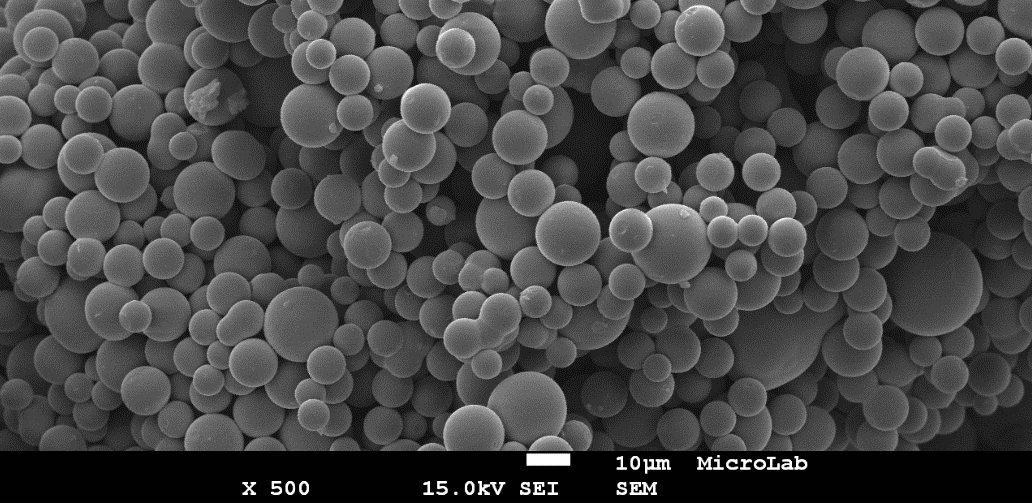

Microcapsules are typically prepared by interfacial polymerization, so that the deep knowledge on their formation, including the tailoring of their shell material, is of key importance when it comes to control and optimize the microcapsules fabrication processes and their performance at the final application. The main goal of this project is to develop an integrated multi-scale approach, involving molecular modeling, kinetics modeling, spatial modeling and experimentation, which will set the basis for the development of tailored polymeric microcapsules, and controlled and optimized processes.

The methodology employed in this study is based on an integrated multi-scale approach, applied to the development of the tailored polymeric microcapsules. The work involves molecular-kinetics-spatial modeling studies, i.e. the analysis of the chemical reactivity of the components using quantum chemical approaches, the development of mechanistic and process models to describe not only the production, but also the performance of these materials.

Furthermore, advanced analytical techniques are used to study the processes from the experimental point of view, supplying relevant data and validating the multi-scale modeling method.

Modeling studies to be performed:

a) Quantum chemical calculations, using a user-friendly commercial program that encompasses semi-empirical, Hartree-Fock and DFT methods. These methods are employed to study reactivity, including transition-states. The quantum chemical calculations are also used to estimate the IR and NMR spectra of the molecules to interpret the experimental data obtained in the monitorization studies by FTIR;

b) Development of reaction/diffusion models that allow the prediction of the behavior of the different species during the formation of the shells. This type of modelling also enables the calculation of the spatial distribution of the different components, including the shell itself, to be compared with micro- and macroscopic observations.

c) Kinetic modelling coupled with thermal modelling; as the polymerization reactions are reasonably exothermic, to interpret data obtained in calorimetry experiments.

Experimental studies to be performed:

a) Microcapsules synthesis, varying specific reaction parameters.

b) Spatial monitorization of the reaction front.

c) Monitorization of the chemical structure (by Fourier Transform Infrared Spectroscopy) along the synthesis.

d) Analysis of the microcapsules´ properties in function of different reaction parameters.

i) Detailed numerical models that can be used in the interpretation of experimental data and predict the reactivity of the different reactants used and the properties of the polymers that are obtained;

ii) Assessment of the microcapsules´ shell thickness, chemical structure and properties and correlation with specific reaction parameters: monomers reactivity, reaction time, reaction temperature, etc;

iii) Validated mechanistic and process models to enable the control and optimization of the microcapsule´s fabrication process and performance for different final applications.